5th PEACE Project Meeting: In Full Swing

Published: October 14, 2025

At the end of September 2025, the PEACE project held its fifth all-hands meeting, kindly hosted by the Eindhoven University of Technology (TU/e). The consortium gathered to assess progress in advancing highly pressurized alkaline electrolysis (AEL) technology.

Fig. 1 TU/e campus, Source: GG (CC-BY-NC-ND 4.0)

With the project entering its final quarter, all work packages are in full swing, and major milestones are just ahead. By the end of summer 2025, the project had already achieved several key research targets:

(1) Pressurized cell qualifications,

(2) Design and production of stack components for high-pressure AEL operation,

(3) Short stack assembly

(4) BTU AEL test site readiness to accommodate the short stack into its pressure vessel

These achievements were thoroughly discussed, and the next steps carefully planned, as short-stack testing will soon pave the way for the full demonstration of the PEACE technology on a 50 kW alkaline electrolysis system capable of handling pressures above 50 bar, expected by the end of this year.

The meeting was opened by the Coordinator, Dr. Fatemeh Razmjooei from the Institute of Engineering Thermodynamics at German Aerospace Center (DLR), who summarised the project’s main achievements. To date, PEACE has delivered seventeen reports to the Clean Hydrogen Partnership (the granting authority), successfully completed its mid-term reporting, and is now focused on assembling, testing, and operating its technology demonstrator.

Work Package 2 – Electrochemical and Gas Purity Tests

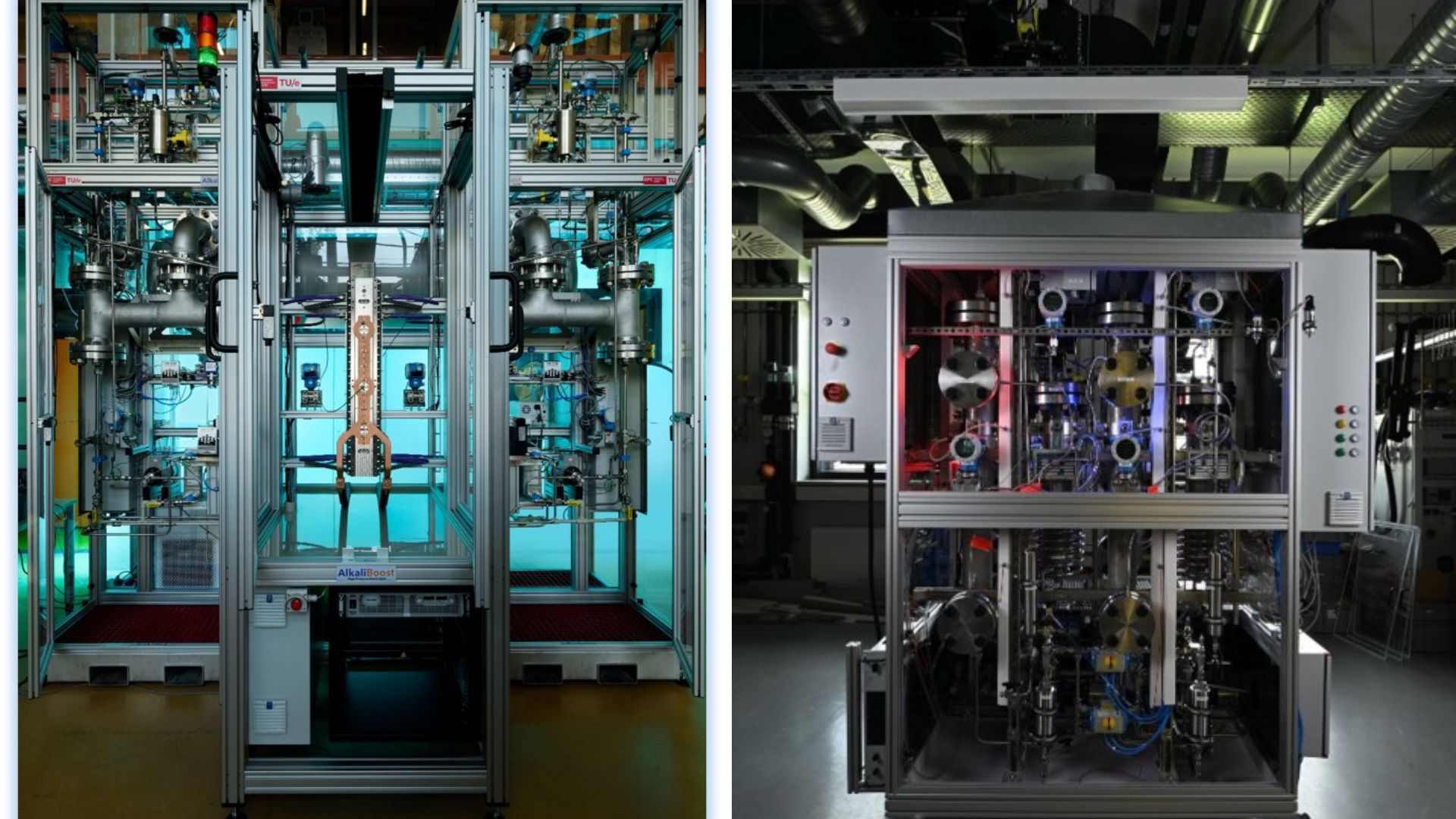

The TU/e and DLR teams presented the latest findings on electrochemical and gas purity testing under pressurized conditions. The project reached to the goal of 1 A cm-2 below 1.8 V with the large cell of 100 cm2 under pressurized conditions.

Fig. 2: Facility used for electrochemical performance testing under pressurized conditions within the PEACE project (left: at TU/e, right: at DLR), Source: TU/e & DLR (CC-BY-NC-ND 4.0)

Work Package 3 – Stack Development

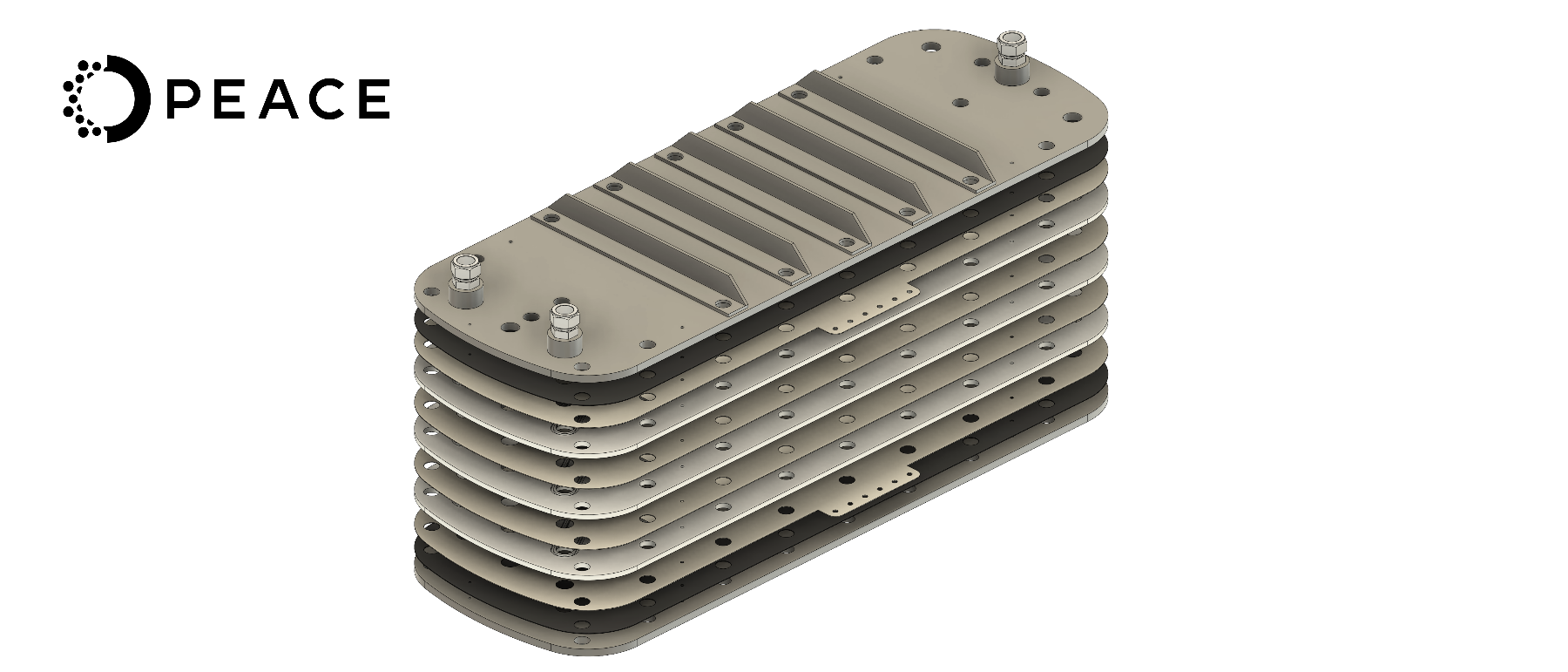

Materials Mates Italia (MMI) produced and assembled a three-cell short stack using previously qualified stack components within PEACE, consisting of: Plastic parts (separator body & gasket press), Metal parts (bipolar plates & current collector plates), Elastic element, Cell components, Sealings and Endplates.

Fig. 3 PEACE short stack (exploded view), Source: MMI (CC-BY-NC-ND 4.0)

The short stack underwent leak and pressure tests to verify mechanical standing and gasket performance. After some adjustments, the stack is to be shipped to the Brandenburg University of Technology Cottbus - Senftenberg (BTU), where it will be mounted into a pressure vessel for high-pressure testing.

Work Package 4 – AEL test site preparation and test protocols

Meanwhile, the BTU team has been preparing its AEL test site to accommodate both the short stack and later the full demonstrator into its pressure vessel. Key Balance of Plant modifications were implemented, and safety approval from TÜV (Technical Inspection Association) is being pursued.

Fig. 4 Simplified Piping and Instrumentation diagram (P&ID) of the PEACE demonstrator at BTU, Source: BTU (CC BY-NC-ND 4.0)

BTU also defined test protocols for the dual-stage alkaline electrolysis system, aligning with EU-harmonised testing protocols for low-temperature water electrolysers. These cover essential operating conditions, including:

· Identification of system range,

· Response time of minimum to maximum system power dynamics

· Response time of nominal to maximum system power dynamics

· Response time of nominal to stand-by system power dynamics

· Time at maximum system power

· Cold start time

· Start-up time from stand-by.

Fig. 5 AEL test protocols literature, Source: BTU (CC BY-NC-ND 4.0)

The system’s performance will be tested under varying temperature and pressure conditions, and durability will be evaluated over up to 500 hours of (nearly) continuous operation, tracking voltage increase rates as an indicator of system stability.

Work Package 5 – Modelling and System Integration

The DLR team presented updates from the TEMPEST modelling framework, which now includes gas crossover parameters. Transient simulations have been performed to study gas purity and stack temperature dynamics.

HyCC and DLR are working on process system design for integrating the PEACE high-pressure AEL system into industrial settings with downstream processes. Three scenarios are being simulated: I) ammonia plant, II) methanol plant, III) hydrogen fuelling station.

The design models will be coupled with Renewable Energy Sources (RES) to simulate how the PEACE hydrogen production process might operate using renewable electricity.

Work Package 6 – Environmental Assessment and Communication

The Technical University of Denmark (DTU) presented its life cycle assessment (LCA) methodology to quantify the environmental impacts of the PEACE technology. A comprehensive life-cycle inventory dataset is being prepared for the PEACE high-pressure AEL process together with a reference data collection. The functional unit has been set to 1kg H2 (99.5 % pure, 80 bar, 80°C), with results scaled to industrial plant level.

Meanwhile, GRANT Garant, continues to ensure active communication and dissemination, maintain a steady outreach through the PEACE website, X and LinkedIn channels, with strong audience engagement. Both the dissemination and exploitation plans were reviewed and strengthened to maximise project impact.

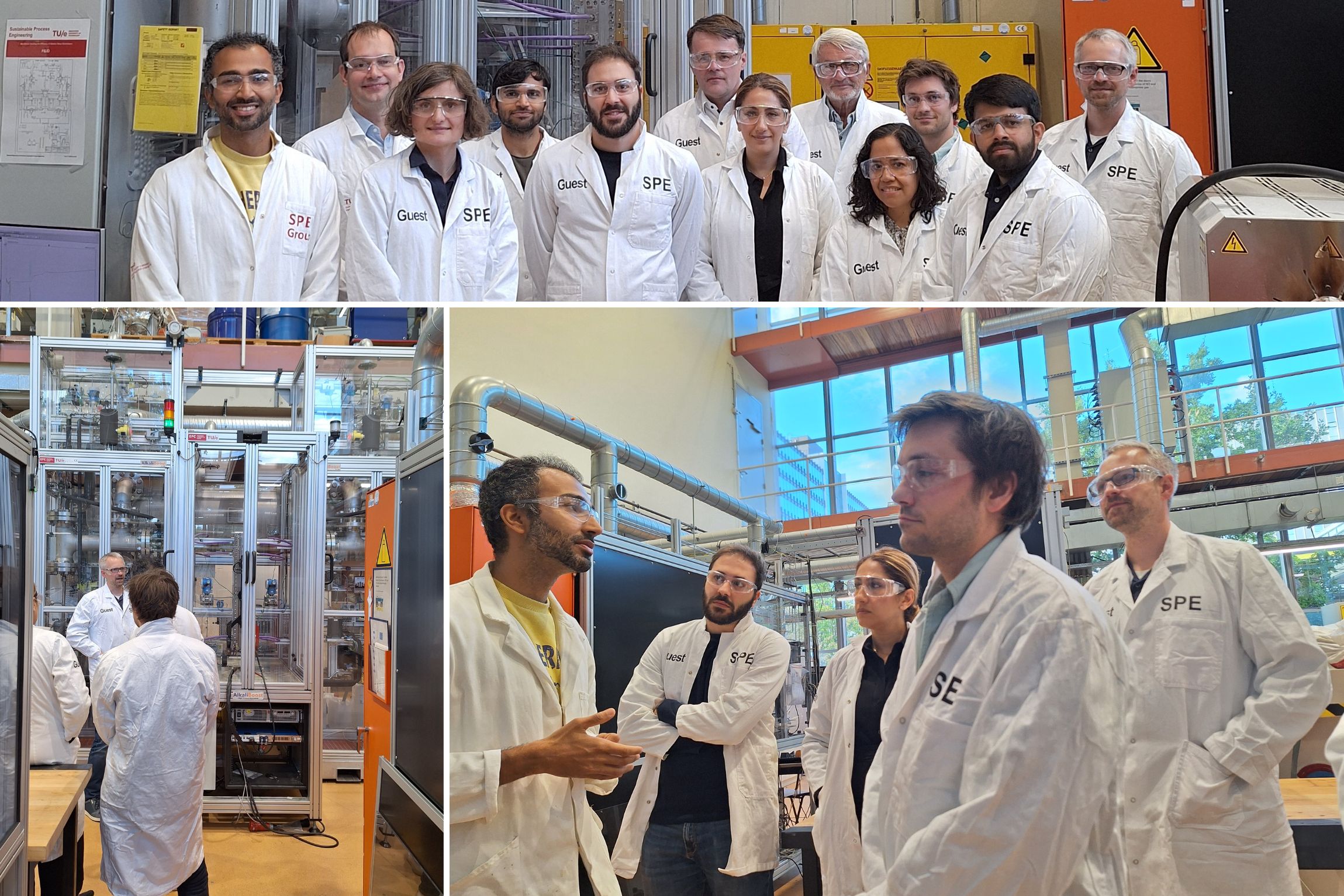

The day, filled with discussions, brainstorming and knowledge exchange, concluded with guided visit to TU/e’s electrochemical laboratory. Their pressurised single cell test rig was on display…

Fig. 6 PEACE consortium on TU/e lab tour, Source: GG (CC BY-NC-ND 4.0)

The project is supported by

the Clean Hydrogen Partnership and its members.

Co-funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or Clean Hydrogen Partnership. Neither the European Union nor the granting authority can be held responsible for them.