Pressurized Efficient Alkaline Electrolyser (PEACE)

PEACE is a research and innovation project funded under the EU Horizon Europe programme. It brings an innovative solution to the reduction of hydrogen production costs by developing a new, efficient alkaline electrolyser while utilising a two-stage pressurisation concept.

The reduction of emissions of carbon dioxide (CO2), represents a significant challenge within the EU Green Deal and for EU’s efforts against the ongoing climate crisis.

This challenge is of outmost importance in order to achieve the goal of a climate-neutral continent by 2050. As early as 2030, the EU plans to reduce greenhouse gases emissions by at least 55%, necessitating the use of higher shares of renewable energy and greater energy efficiency. To meet these goals, the production of green hydrogen through electrolysis (powered by renewable sources) offers a viable solution.

That´s why the PEACE project focuses on:

- developing innovative high-pressure alkaline electrolysis technology

- substantially reducing hydrogen production costs

- enhancing the integration of the hydrogen production with its subsequent utilisation within the chemical industry

- quantifying the environmental impacts of its groundbreaking technology through a life cycle assessment (LCA)

- enhancing the competitiveness of the hydrogen economy

Our objectives

We aim to contribute to a sustainable and low-emission European society by reducing the levelized cost of hydrogen (LCOH) through the development and demonstration of a 50kW low-temperature alkaline water electrolysis system capable of operating at pressures more than 50bar.

High-efficiency

stack development

Thorough stack components development and qualification with an emphasis on non-noble metals utilisation.

Pressure vessel

stack concept

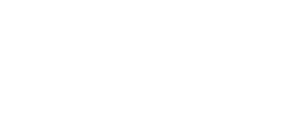

Development of a pressure vessel stack reaching more than 50bar operation pressures – dual-stage pressurization concept.

BOP and auxiliary

optimization and qualifications

Balance of Plant (BOP) design addressing challenges of a high-pressure operation.

Technology

demonstration

Assembling and operating an innovative alkaline electrolysis system > 50kW with staged pressure handling more than 50bar.

Integration concept

with downstream chemical plants

Concept of an effective further use of the PEACE-produced hydrogen in a chemical plant hydrogen piping network to serve the key downstream processes.

Reduction of capital

costs per system

Reducing the capital costs of a hydrogen production unit.

The project is supported by

the Clean Hydrogen Partnership and its members.

Co-funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or Clean Hydrogen Partnership. Neither the European Union nor the granting authority can be held responsible for them.